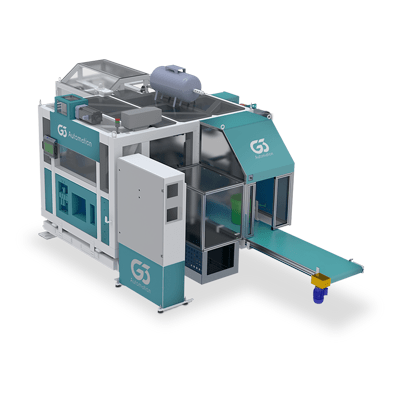

Designed to meet ultra-fast injection cycles, the Automation Cell for Cutlery and related is able to work with total injection cycles as short as 4.0 seconds, with extraction between 0.7 to 1 second, depending on the product to be handled.

It comes with a tubular steel structure, extremely rigid, extraction arm and claw made of aluminum and carbon fiber, onferring strength and lightness to the assembly, enabling accelerations around 5G (approx. 50 m/s²).

With precise movements, it ensures the extraction and the stacking of the parts in an agile and safe way, reducing the use of manpower and allowing to extract the maximum performance from the injection/mold/robot set.

Areas of application

- Cutlery handling and similar

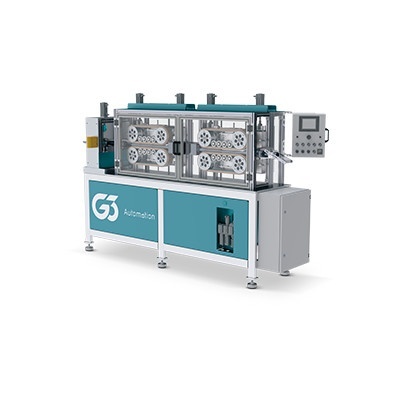

Integration with KUKA® robot

It has a Kuka® 6 axis robotic arm, for the organized transport of the cutlery to the flowpack packaging area.

Fairing NR12

Robust and resistant structure, in accordance with the NR12 safety standard. Strategically placed light curtain sensors interrupt its operation of the in case the operator goes inside.

Intuitive controller

The HMI has a 10″ touchscreen, with a friendly interface entirely in Portuguese.

Integration with flowpack packer

This way, it is able to deliver the cutlery already packed and without any manual contact.

Videos

Differentials

- 100% national manufacturing

- Financial possibility by BNDES or FINAME cards

- Ideal for handling forks, knives, disposable spoons and similar

- Manuals and other technical materials entirely in Portuguese

- Free of importing taxes

Specifications

External width (mm):

Customizable

Max. side arm speed (m/s):

5

Side arm forward stroke (mm):

Customizable

Max. side arm load – with no gripper (kg):

Customizable

Max. side arm acceleration (m/s²):

50

Voltage (V):

380 (three-phase)

Air intake (bar):

6

Machine to machine communication:

Euromap 12/67/73

Telescopic arm:

Product output conveyor: