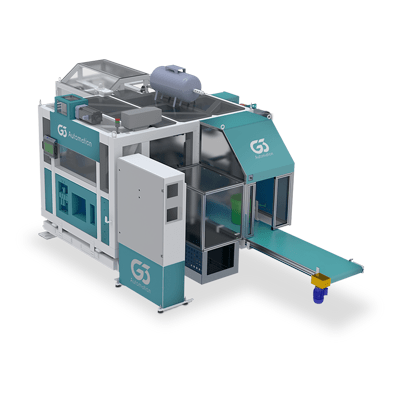

This automation was developed to handle popsicle sticks, which are deposited in bulk, lined up, checked by camera detection and organized in magazines.

At the end of the cycle, the sticks are delivered grouped and ready for the ice cream preparation stage. Thus, there is a significant gain in productivity, due to the time savings that the equipment provides.

Relying on the strengths of G3 Automation automations, the Popsicle Stick Handler helps the ice cream industry to leverage its productivity, being able to release up to 50,000 sticks per hour.

It has robust fairing, with safety according to technical standard, high precision in its operations, agile movement, double filling system and detection of irregular sticks.

The Ice Cream Stick Manipulator is the best choice for those looking for a new level of performance and competitiveness.

- Popsicle stick automated handling

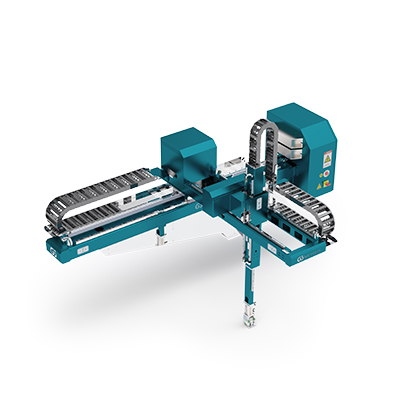

Dual supply

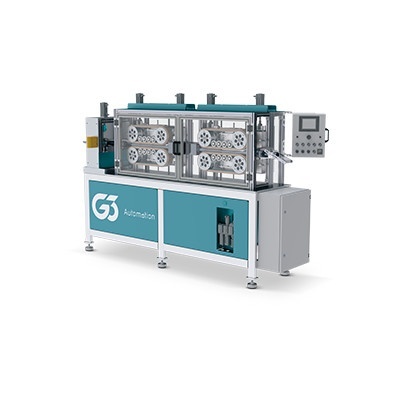

The automation has two cutlery handling systems that work in parallel.

Fairing NR12

Robust and resistant structure, in accordance with the NR12 safety standard.

Intuitive controller

The HMI has a 7″ touchscreen, with a friendly and entirely in Portuguese interface.

Camera detection system

Camera monitors the shape of the sticks and discards those that are outside the standard.

Video

Differentials

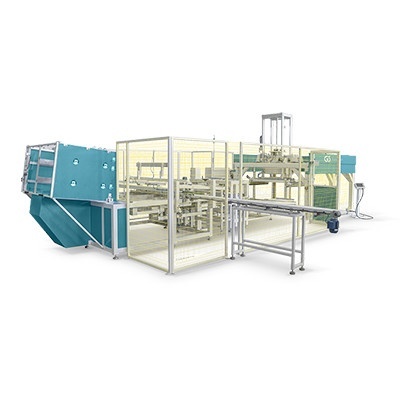

- 100% national manufacturing

- Financial possibility by BNDES or FINAME cards

- Adaptable to many types of products and boxes

- Free of importing taxes