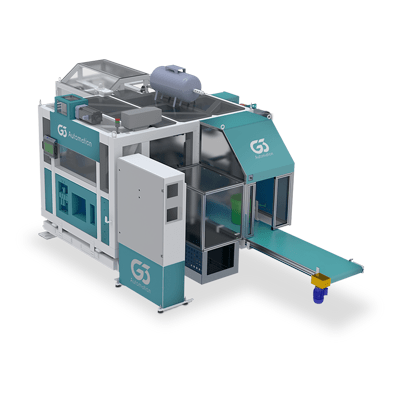

Developed for the process of application of caps on tubes and jars by pressure, the tube capping machine shows as a complete solution, receiving the components to reorganize them into an agile and precise assembly line.

It produces 120 sets per minute,and is able to meet an even broader production capacity, according to the client’s needs. It has a robust and safe fairing, in accordance with NR 12, avoiding any contact of the operator with the moving parts of the equipment, in addition to an intuitive touchscreen HMI interface for quick system configuration.

The tube capping machine is the ideal solution for those who need to automate capping processes or similar assemblies.

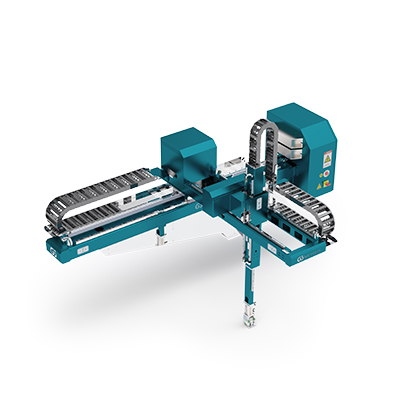

Areas of application

- Applying caps to test tubes

- Assembling similar parts

Complete automation

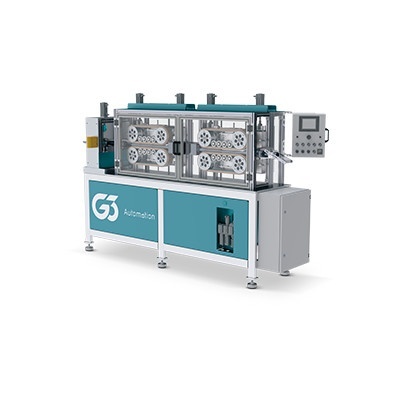

The equipment performs operations of organization, alignment, positioning, and assembly of tubes and caps.

Fairing NR12

Robust and resistant structure, in accordance with the NR12 safety standard.

Intuitive controller

The HMI has a 7″ touchscreen, with a friendly and entirely in Portuguese interface.

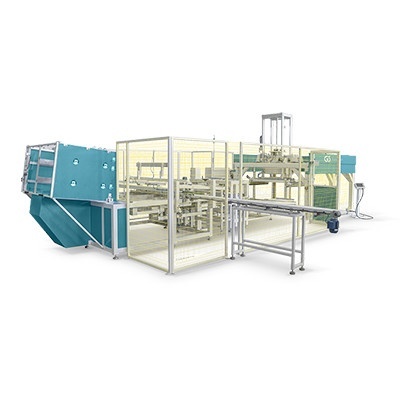

Uninterrupted production

The equipment performs a count of the parts released, alternating the side on which they are deposited to allow the exchange between full and empty boxes without interrupting the process.

Videos

Differentials

- 100% national manufacturing

- Financial possibility by BNDES or FINAME cards

- Manuals and other technical materials entirely in Portuguese

- Free of importing taxes

- Adaptable to customer needs